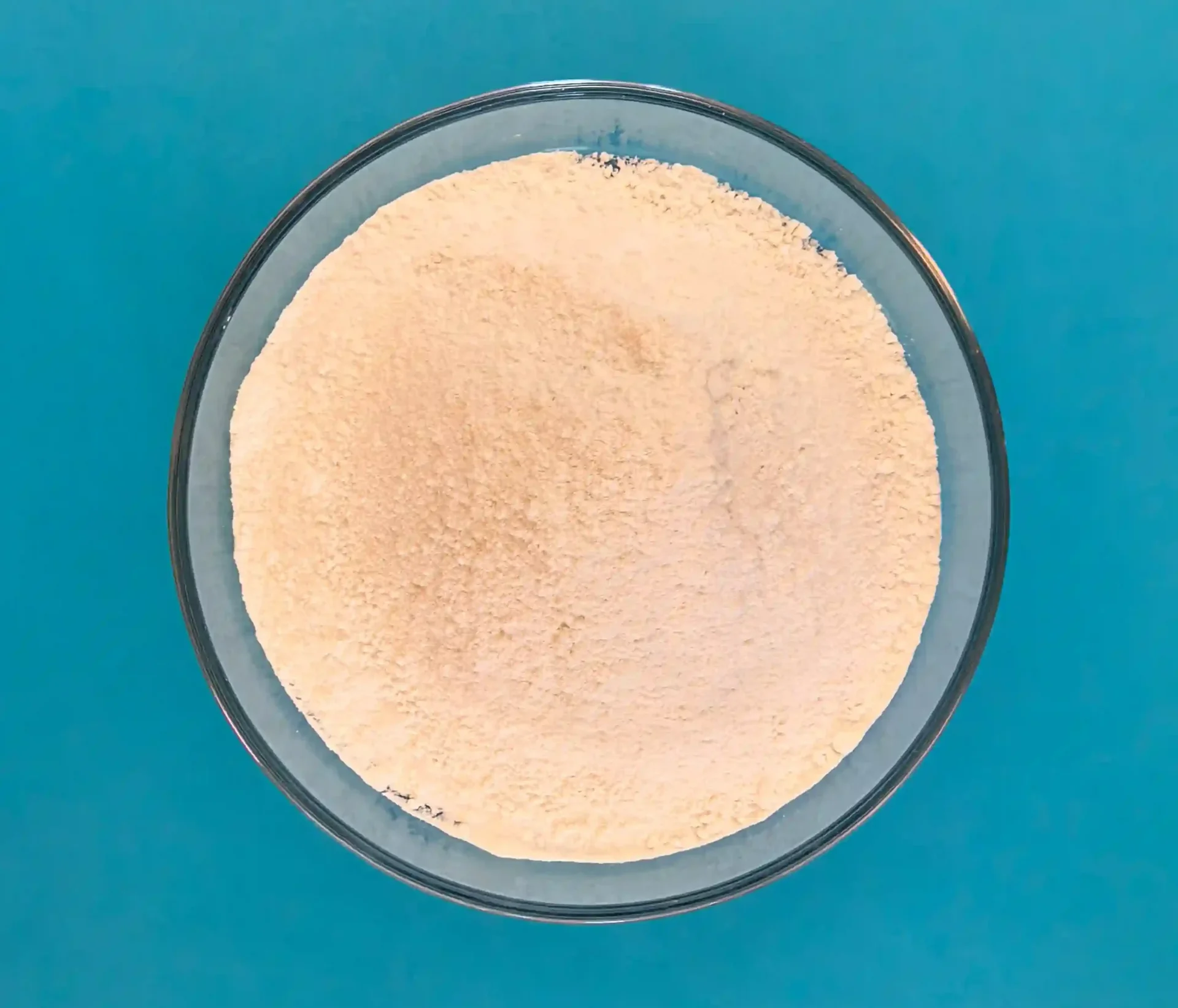

Zinc carbonate is produced by reacting zinc-containing raw materials (such as zinc oxide, zinc ash, and zinc slag) with sulfuric acid to generate zinc sulfate solution, which is then reacted with soda ash to precipitate zinc carbonate. We use high-quality raw materials, multi-stage impurity removal processes, state-of-the-art equipment, and top-tier technology. The process involves dissolution, heating, and pressure filtration. From the synthesis of zinc carbonate, multiple methods are used to control reaction conditions, ensuring that zinc carbonate particles are generated under controlled conditions. After synthesis, the mixture is washed, separated into solid and liquid components using a diaphragm filter press, dried by airflow, classified by particle size, and then passed through a vibrating screen before packaging. Zinc carbonate is used in medicine as a skin protectant; in animal feed as a zinc supplement; and in the synthesis of high-purity zinc stearate. In rubber processing, zinc carbonate increases the thermal conductivity of rubber compounds, improving their thermal conductivity and vulcanization speed, making it particularly suitable for hot air vulcanization processes. It also improves the shape stability of semi-finished products during vulcanization, which is suitable for moldless products (such as many extruded products using continuous vulcanization processes).

Tìm Sản Phẩm Của Chúng Tôi

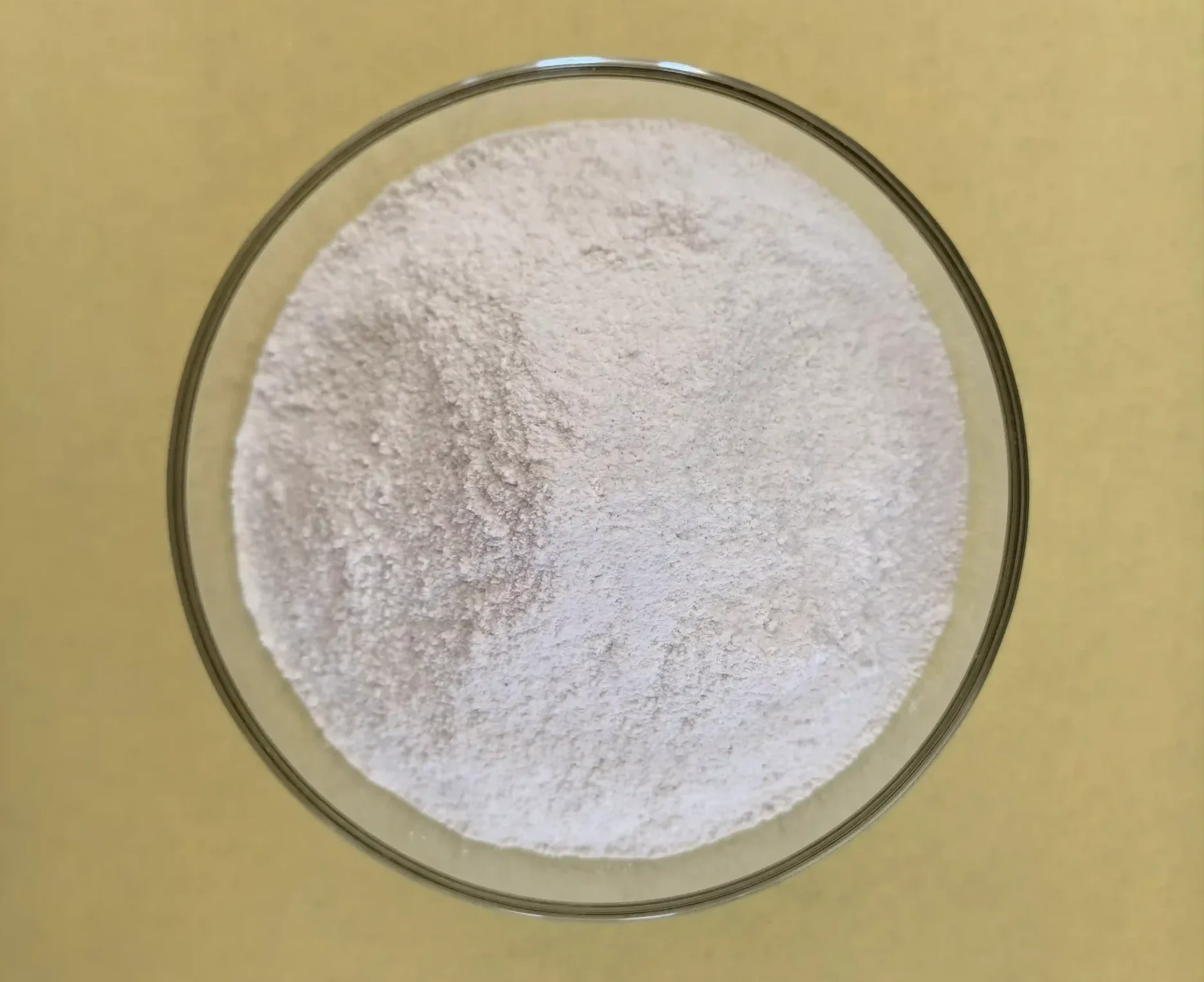

Kẽm Cacbonat

Danh Mục Sản Phẩm

Blog

Mô tả ngắn:

Kẽm cacbonat có thể được sử dụng trong các sản phẩm cao su trong suốt, cao su màu và các sản phẩm nhựa xốp, v.v.

- Thẻ: kẽm cacbonat cơ bản, Mua Canxi cacbonat, Kẽm cacbonat hoạt tính cao, Kẽm cacbonat tinh khiết cao, Khuyến mãi nóng: Carbonat kẽm, Kẽm cacbonat có hàm lượng tạp chất thấp, kẽm cacbonat, Nhà máy sản xuất carbonate kẽm, Kẽm cacbonat cho ngành công nghiệp hóa chất, Kẽm cacbonat cho cao su, Giá của kẽm cacbonat, Bán buôn carbonate kẽm

Chi tiết sản phẩm

Parameter table

| Analysis Item | Specification Index | Tested Data |

| Zinc Content, Calculated as Zn | ≥57% | 57% |

| Lead Content, Calculated as Pb | ≤0.0015% | 0.0005% |

| Arsenic Content, Calculated as As | ≤0.0005% | 0.002% |

| Cadmium Content, Calculated as Cd | ≤0.001% | 0.0005% |

| Manganese Content, Calculated as Mn | ≤0.005% | 0.002% |

| Loss on Ignition | 25.0-30.0 | 27.5 |

| Moisture Content | ≤2.5% | 2% |

| Screening Rate, Through 75 μm | ≥99% | 99.8 |

| Sulfate Ion, SO₄²⁻ | ≤0.6% | 0.5% |

| Bulk Density | 0.3-0.4 | 0.32 |

| pH Value | ≥8 | 8.5 |