Active Zinc Oxide – K90R

In many rubber manufacturing processes, conventional zinc oxide often shows low utilization efficiency, leaving excess residue after vulcanization and limiting overall product performance. Active Zinc Oxide K90R, developed by Jiangsu Daoan Chemical Co., Ltd., is formulated to address these challenges through higher reactivity and more effective participation in the curing system.

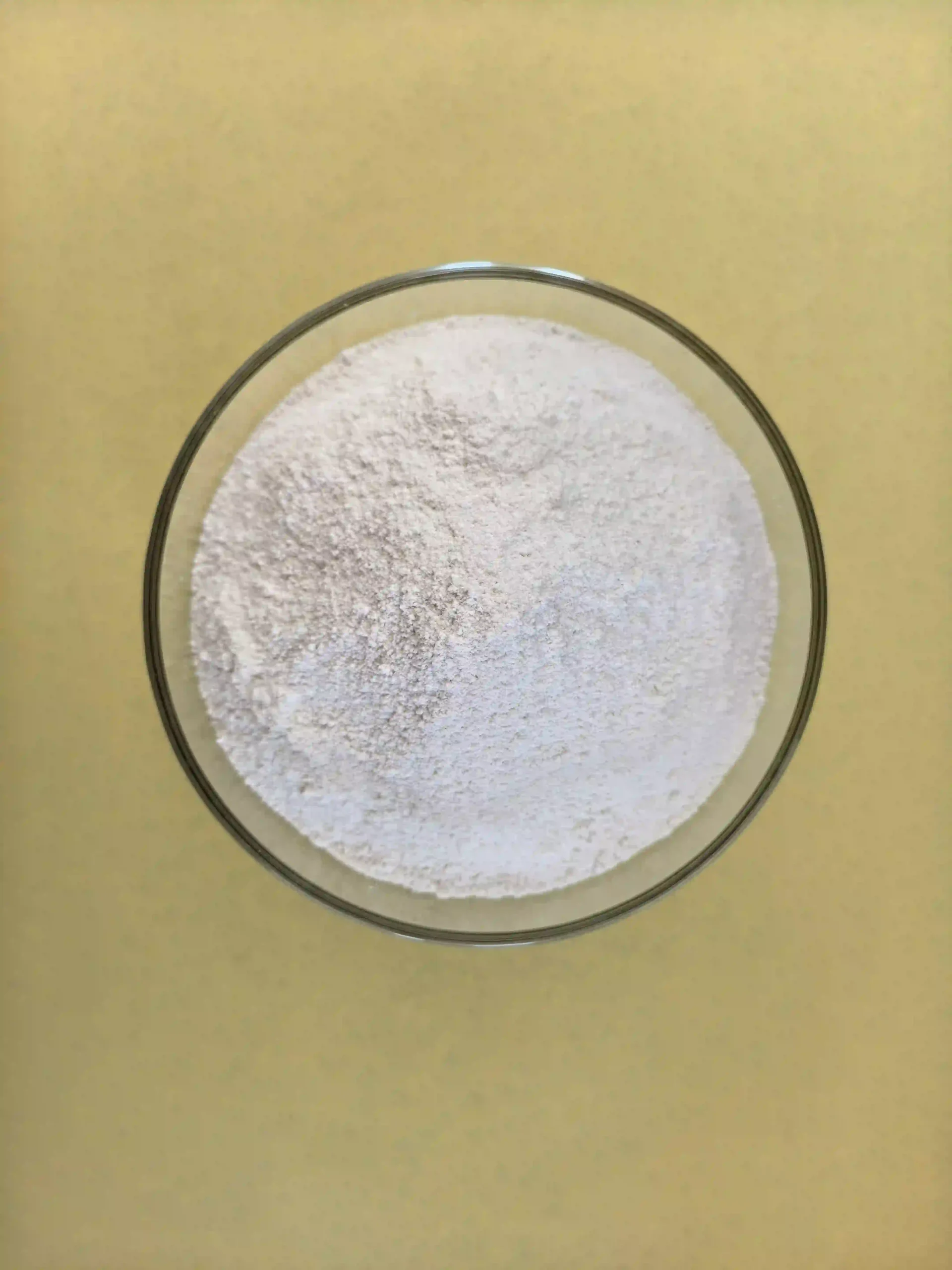

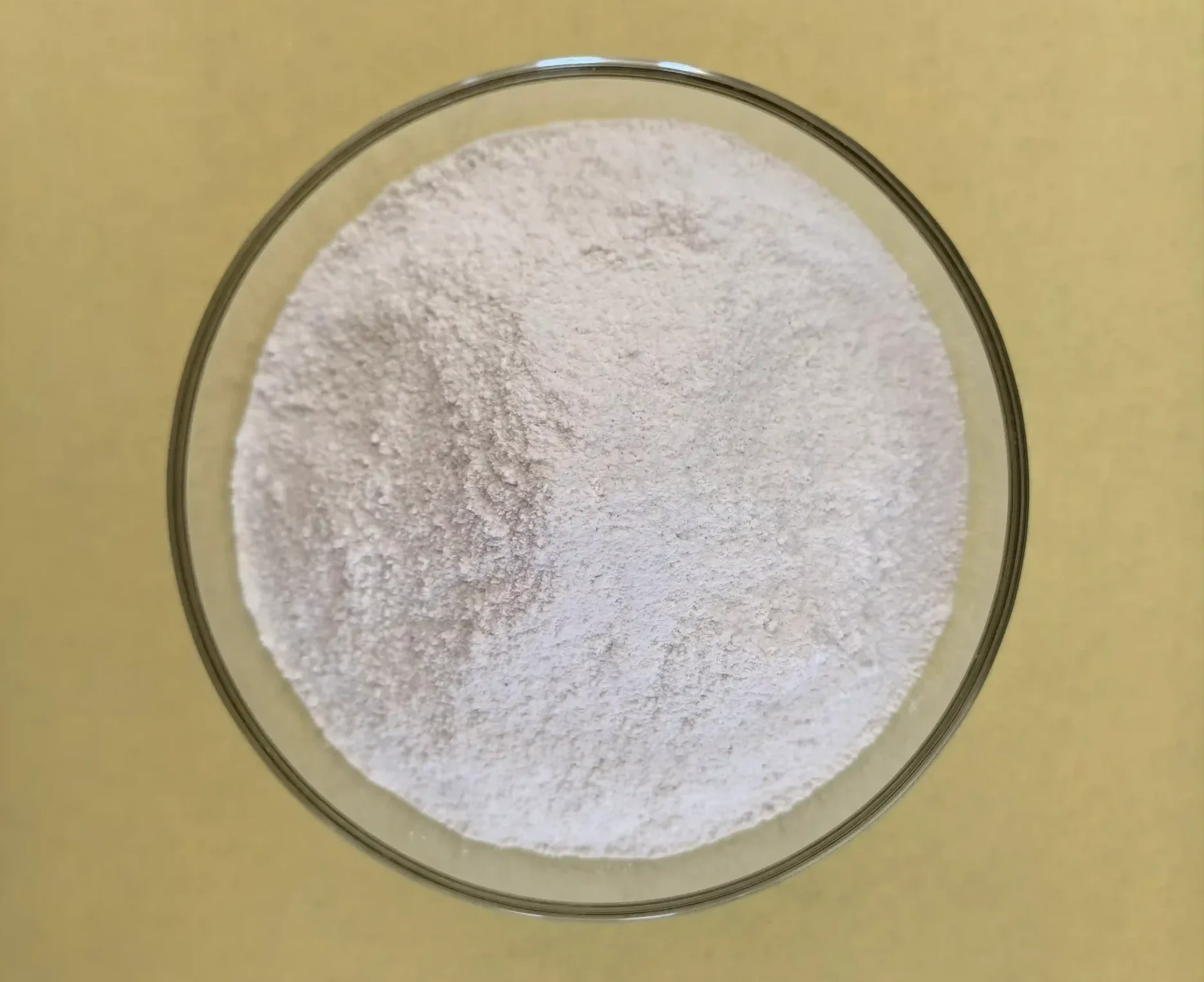

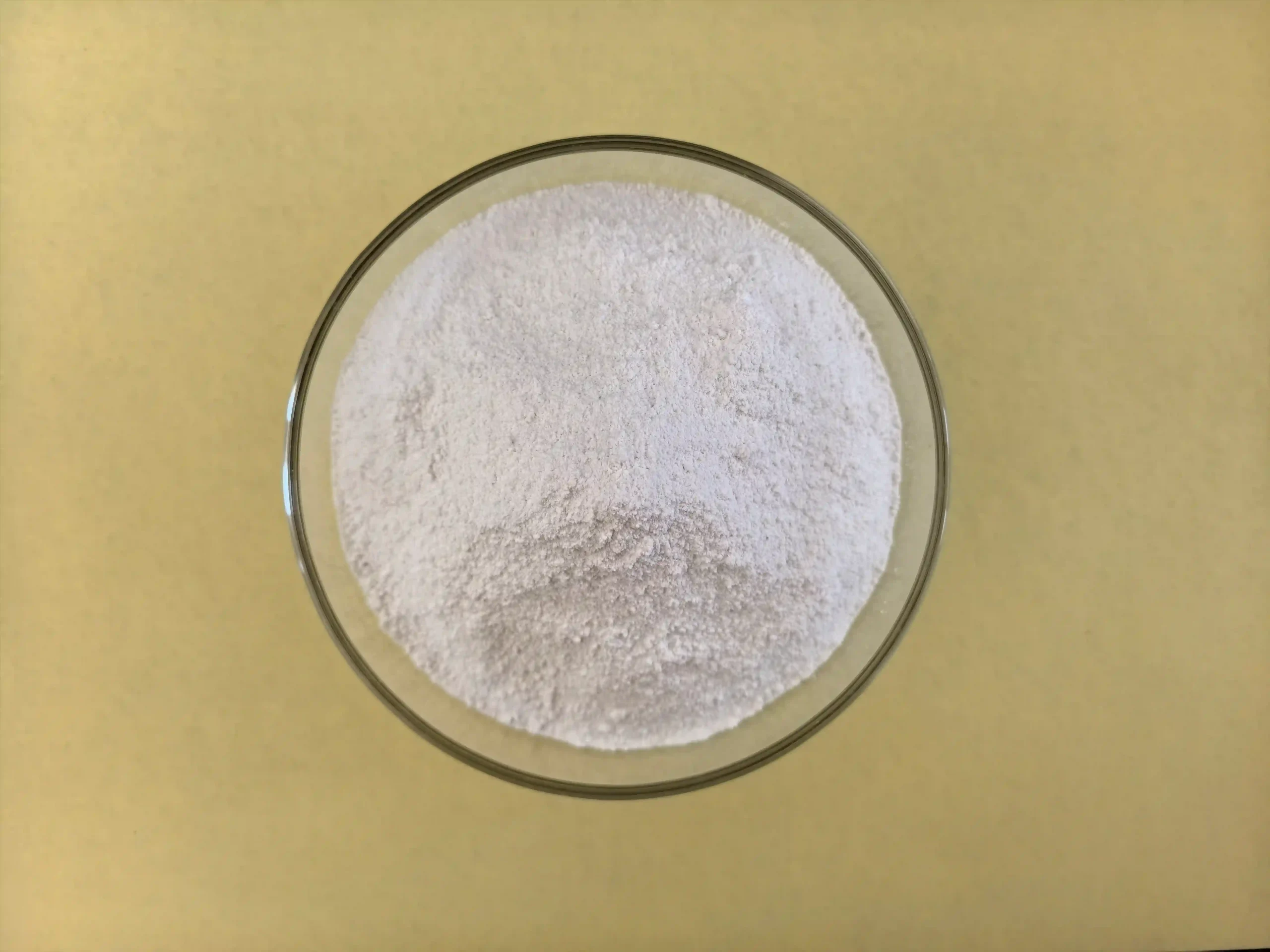

Produced via a controlled wet chemical process, Active Zinc Oxide K90R appears as a pale yellow to white powder with a refined particle structure. This structure allows the material to disperse smoothly within rubber compounds and respond quickly during vulcanization, enabling it to replace traditional 99.7% purity zinc oxide while significantly reducing post-curing residue.

From a processing standpoint, Active Zinc Oxide K90R helps improve zinc utilization by accelerating the interaction between zinc oxide and rubber. Better heat distribution within the compound supports more complete vulcanization, which directly contributes to improved aging resistance and longer service life of finished rubber products.

The practical outcome of using Active Zinc Oxide K90R is a more compact and stable cross-link network in rubber materials. Faster curing cycles, improved mechanical strength, and consistent physical properties make it a reliable choice for manufacturers seeking both quality improvement and process optimization.

As a result, Active Zinc Oxide K90R is applied across a broad range of rubber products, including rubber shoe soles, molded and extruded goods, rubber hoses and belts, automotive rubber components, tires, inner tubes, and medical rubber products. Its environmental compatibility and low heavy metal content further support its use in regulated and high-performance applications.

For logistics and handling, Active Zinc Oxide K90R is supplied in 20 kg bags. Fifty bags are stacked on one pallet, with a net weight of 1,000 kg per pallet. Each standard container can carry 20 pallets, reaching a total net weight of 20 tons in line with international transportation standards.