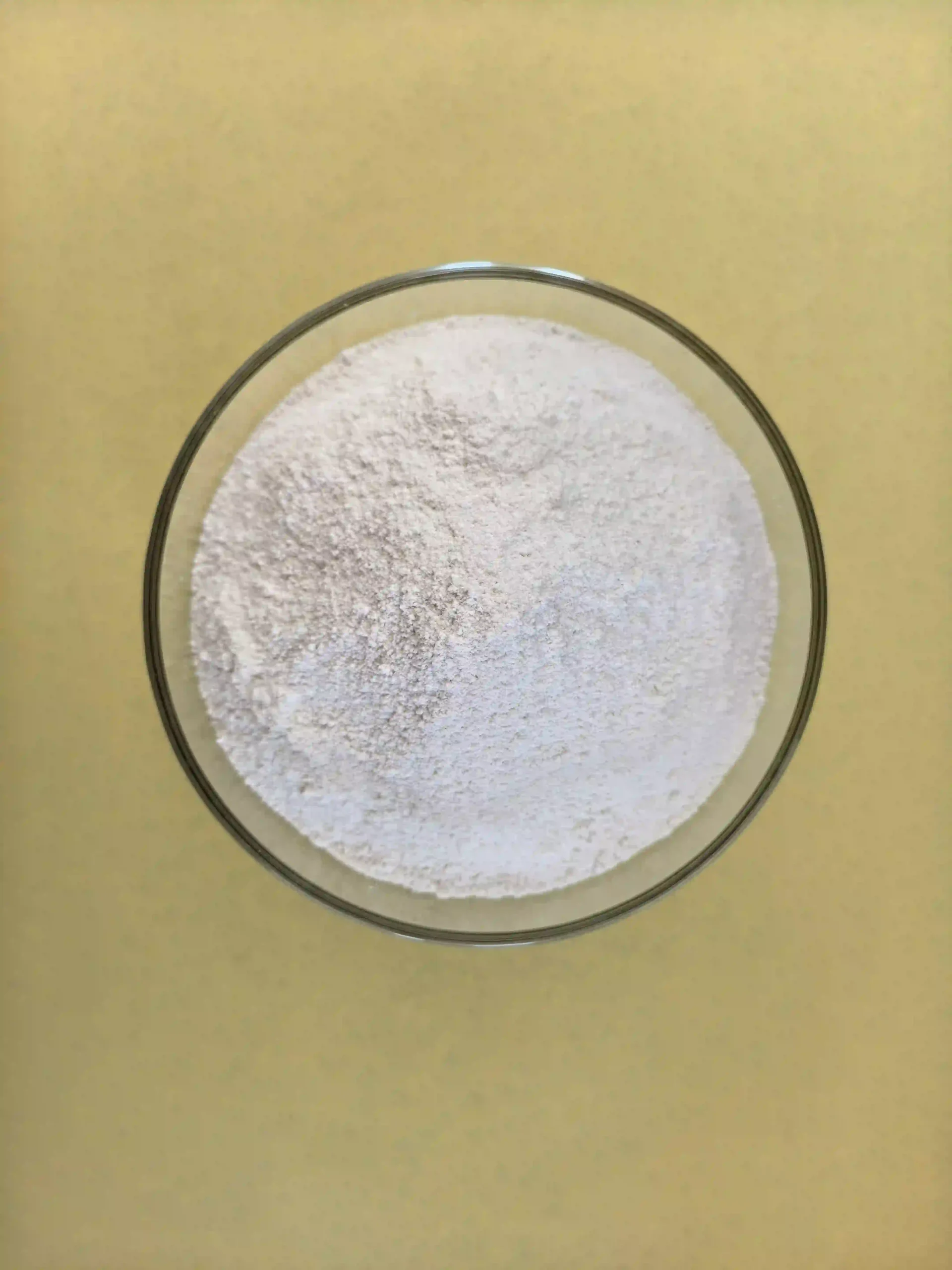

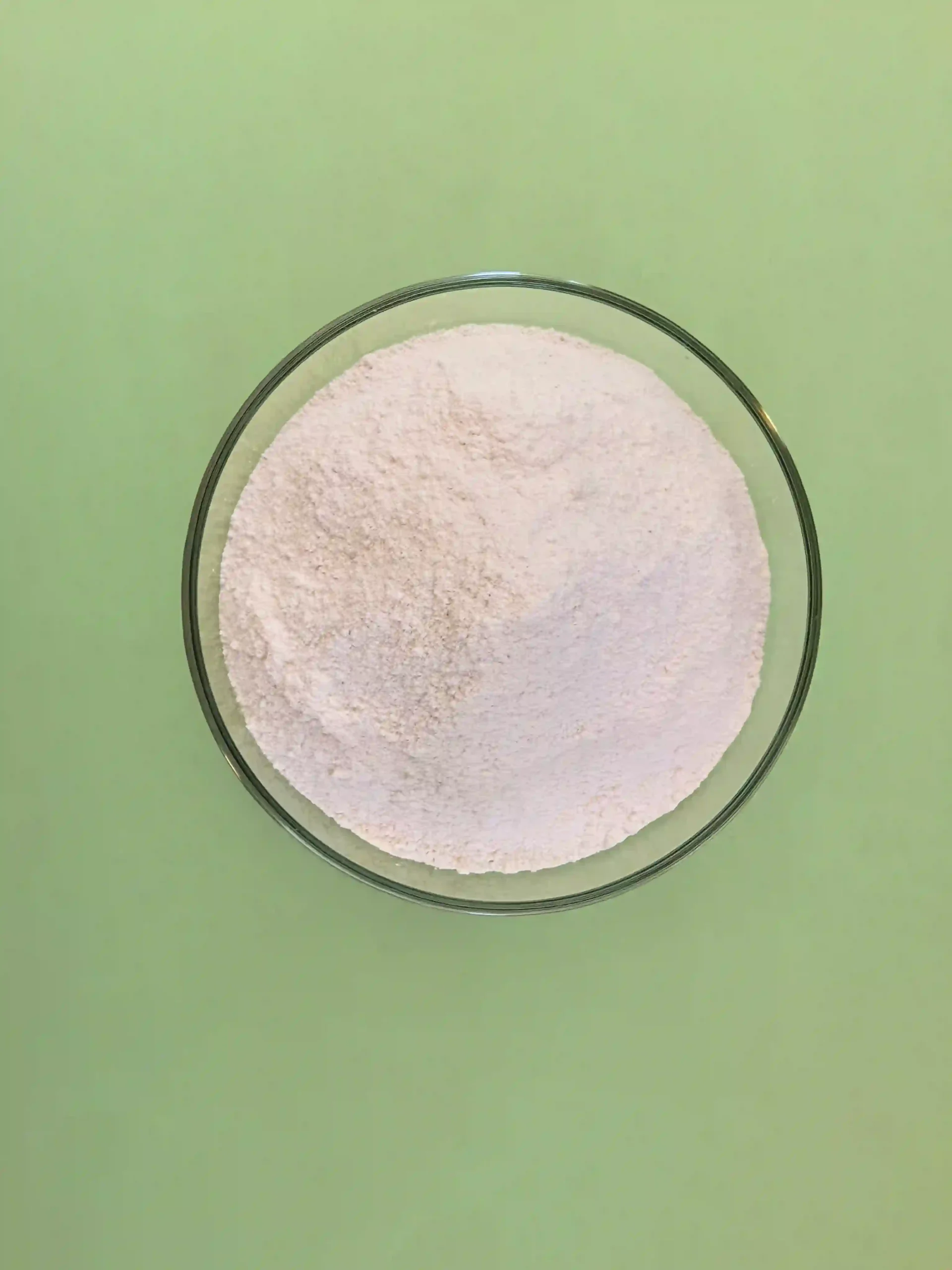

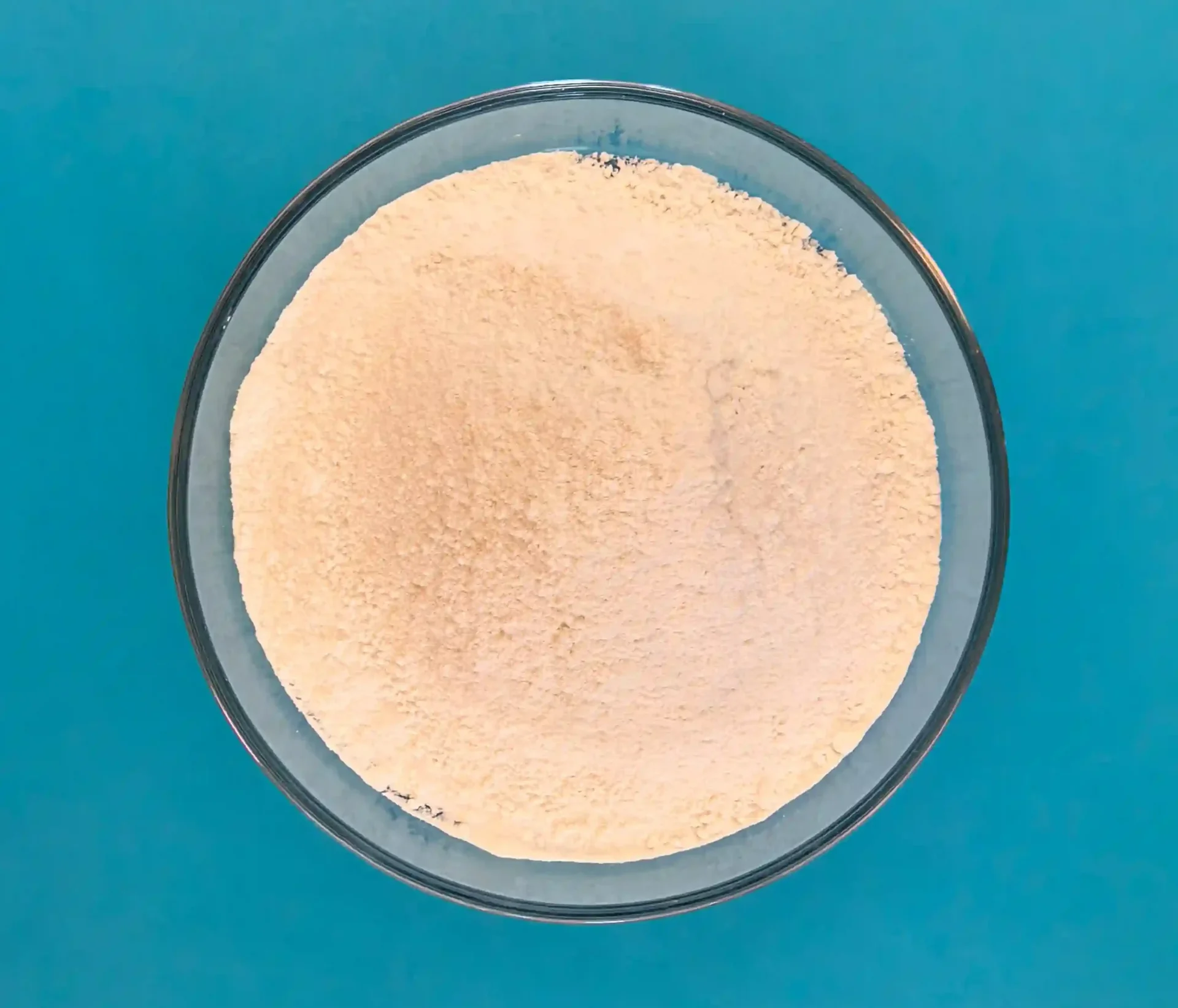

Granular Zinc Oxide appears as pale yellow granules, formulated entirely from high-activity zinc oxide powder. It leverages an innovative carrier-free microgranulation process to create differentiated advantages. Unlike conventional granulation technologies, this advanced process avoids damaging the inherent properties of the powder throughout production, thereby fully preserving the raw material’s excellent high dispersibility from the source. In diverse application scenarios such as rubber vulcanization, coating formulation, and feed processing, it can rapidly and uniformly integrate with other substrates without the need for additional dispersing agents. This effectively prevents agglomeration issues, significantly enhancing the production efficiency of downstream products and the stability of finished product quality.

Highly adaptable to industrial production needs, Granular Zinc Oxide exhibits excellent compatibility with automatic metering and conveying systems. Its regular granular form ensures superior fluidity in screw conveyors, quantitative feeding equipment, and other machinery, enabling precise controlled dosage addition. This not only reduces raw material waste caused by metering errors but also adapts to the automated operation processes of large-scale continuous production lines, helping enterprises reduce costs and enhance efficiency. Meanwhile, the granular structure fundamentally addresses the industry pain point of dust emission associated with traditional powdered zinc oxide during feeding and transportation, drastically reducing dust pollution in the workplace, effectively safeguarding the occupational health of operators, and fully complying with modern industrial hygiene standards and environmental production requirements. It provides strong support for enterprises to build green and compliant production environments.

While ensuring performance and environmental advantages, Granular Zinc Oxide possesses excellent compressive strength. Even in complex logistics scenarios such as long-distance transportation and multi-layer stacked storage, it can effectively resist external impact, maintain the integrity of the granular structure, and prevent secondary crushing that may generate dust or affect usability.

Granular Zinc Oxide boasts a wide range of applications, including rubber molded products, extruded products, rubber-plastic foam materials, rubber hoses and belts, automotive rubber components, tires, inner tubes, medical rubber products, as well as the zinc salt chemical industry and other fields.

Packaging and Transportation of Granular Zinc Oxide

- Adopts a packaging specification of 20 kg per bag, with 50 bags stacked on each pallet, resulting in a net weight of 1,000 kg per pallet.

- Each container can carry 20 pallets, with a total net weight of 20 tons.