Active Zinc Oxide – K90

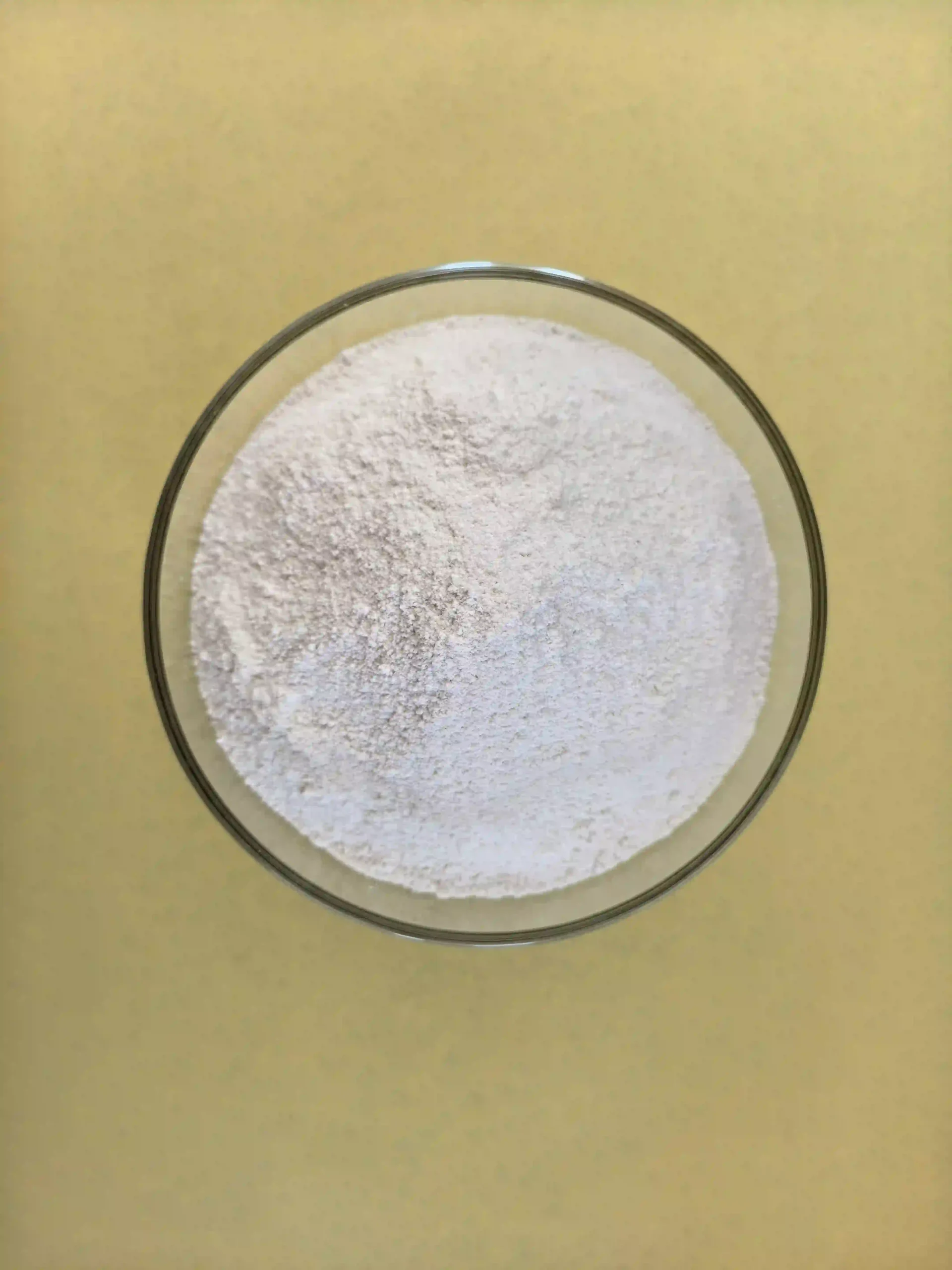

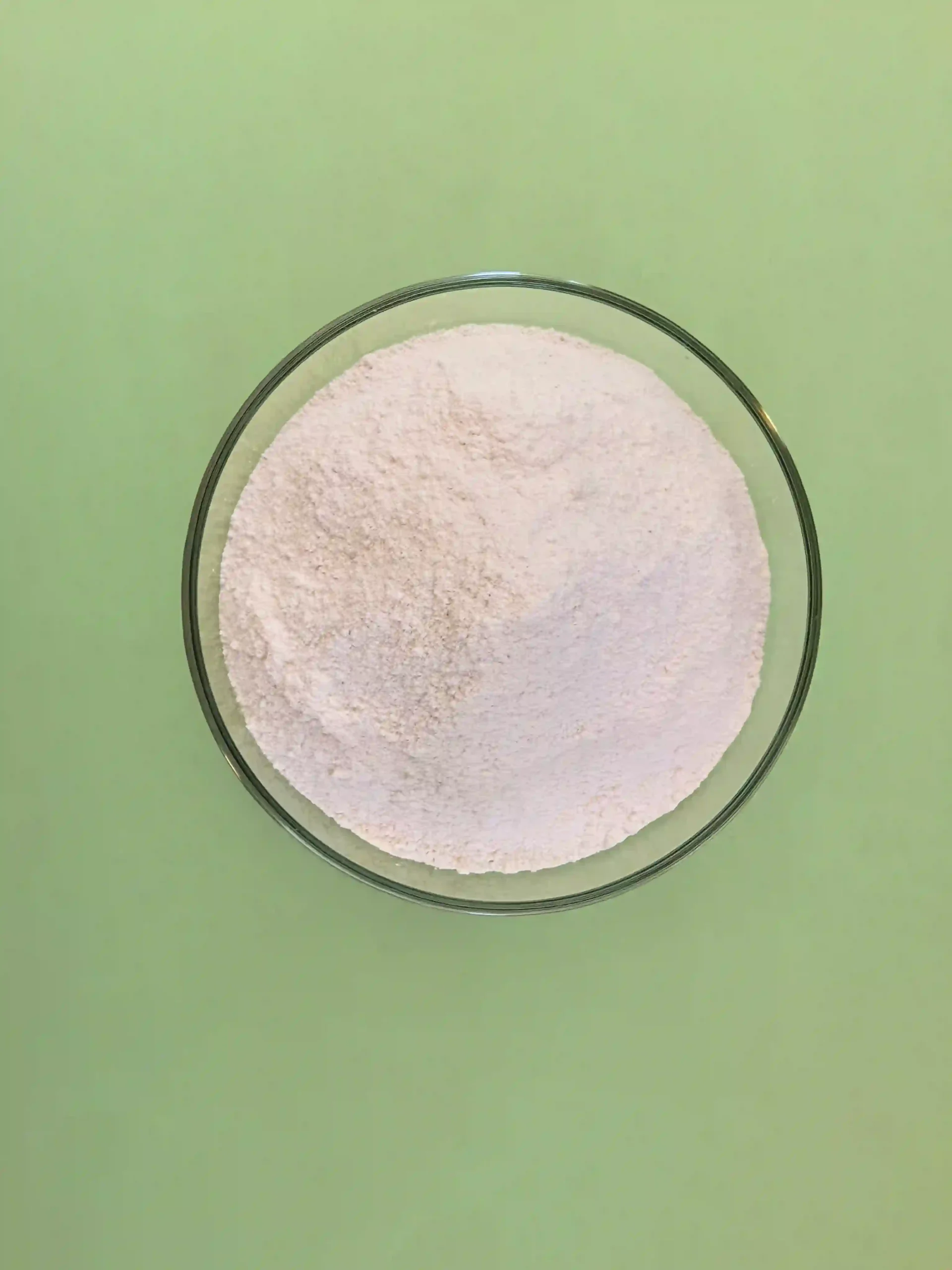

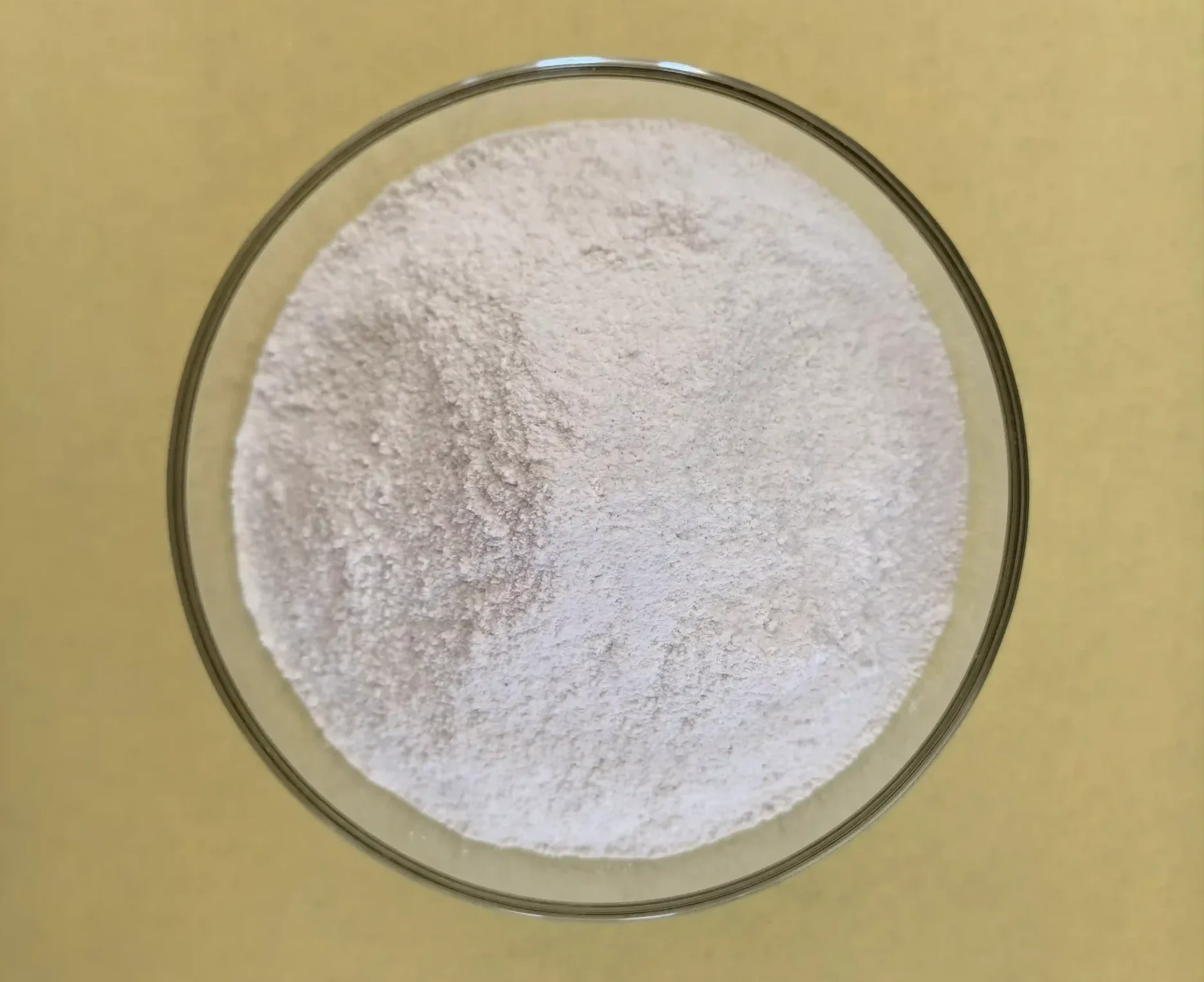

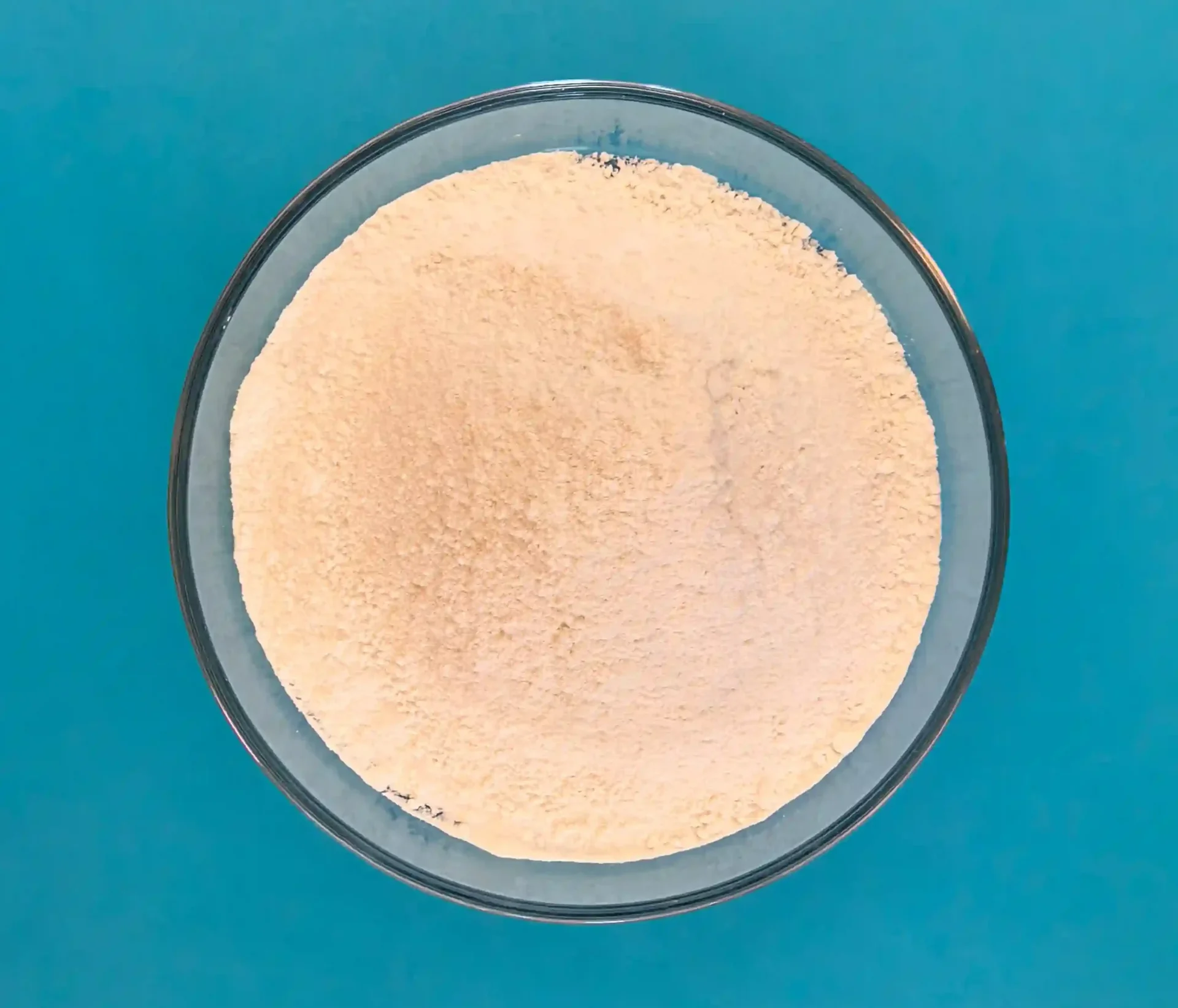

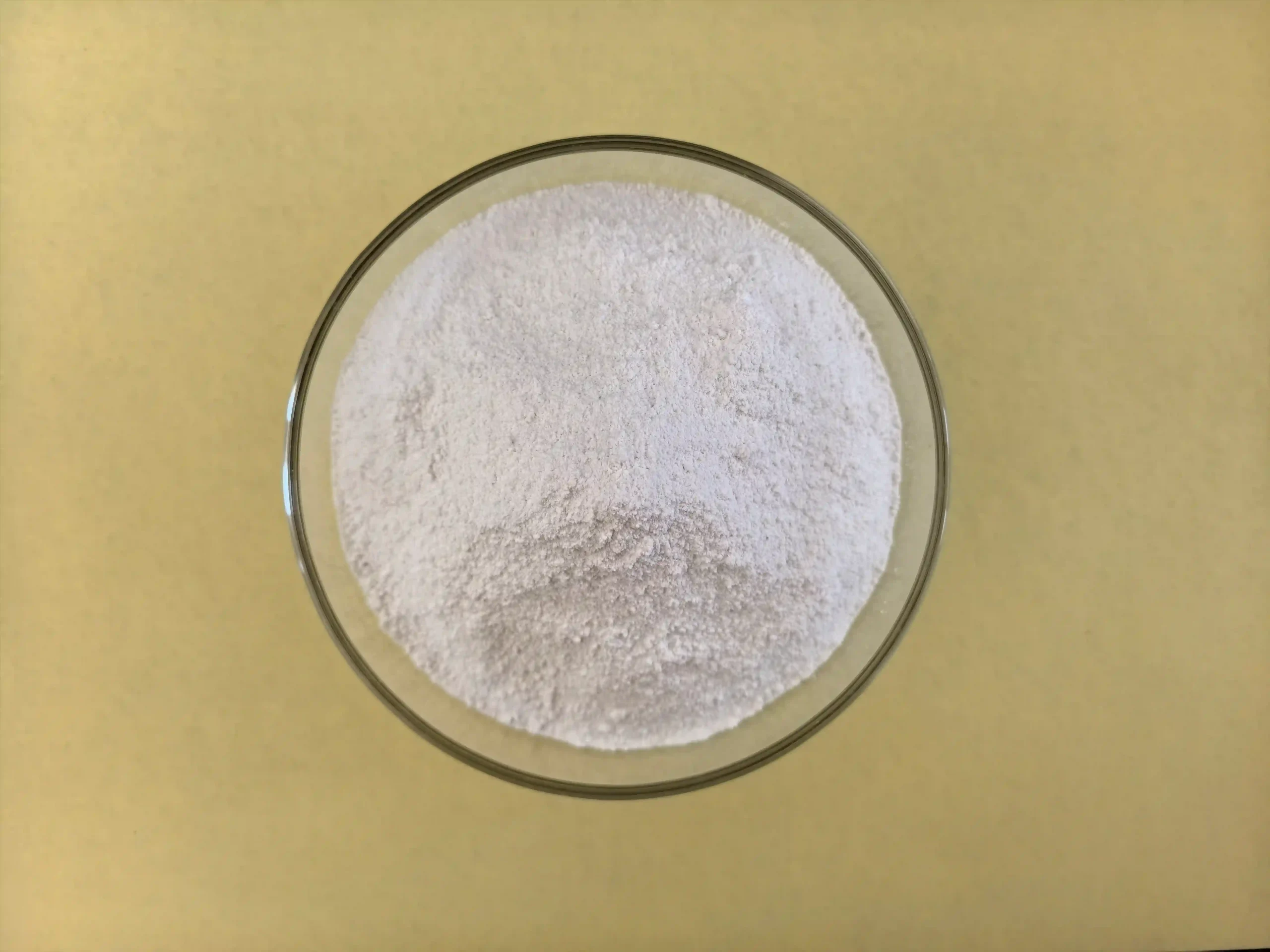

Manufactured by Jiangsu Daoan Chemical Co., Ltd., Active Zinc Oxide K90 is a wet-process zinc oxide designed for efficient activation in rubber systems. The material appears as a pale yellow to white powder, offering stable quality supported by Daoan’s mature production lines and strict management standards.

Why K90 Performs Better in Rubber Systems

The performance of Active Zinc Oxide K90 comes from its optimized particle structure. With a large specific surface area and fine particle size, the product disperses rapidly in rubber compounds and participates more effectively in vulcanization reactions. Compared with ordinary 99.7% zinc oxide, K90 reduces inactive zinc oxide residue after curing and improves overall utilization efficiency.

In practical rubber processing, Active Zinc Oxide K90 accelerates the reaction between zinc oxide and rubber, shortens curing time, and promotes uniform heat transfer. This leads to more complete vulcanization, tighter cross-link networks, and improved aging resistance. Finished rubber products benefit from enhanced mechanical strength, durability, and extended service life.

Typical Application Scenarios

Active Zinc Oxide K90 is suitable for a wide range of rubber products, including:

– Rubber shoe soles

– Molded and extruded rubber goods

– Rubber hoses and tapes

– Automotive rubber components

– Tires and inner tubes

– Medical rubber products

Its consistent activity and environmental friendliness make it a reliable alternative to conventional zinc oxide in both general and high-performance formulations.

Packaging & Logistics

Active Zinc Oxide K90 is supplied in 20 kg bags. Fifty bags are stacked on one pallet, resulting in a net weight of 1,000 kg per pallet. A standard container can load 20 pallets, with a total net weight of 20 tons, meeting standard international transportation requirements.