Find Our Products

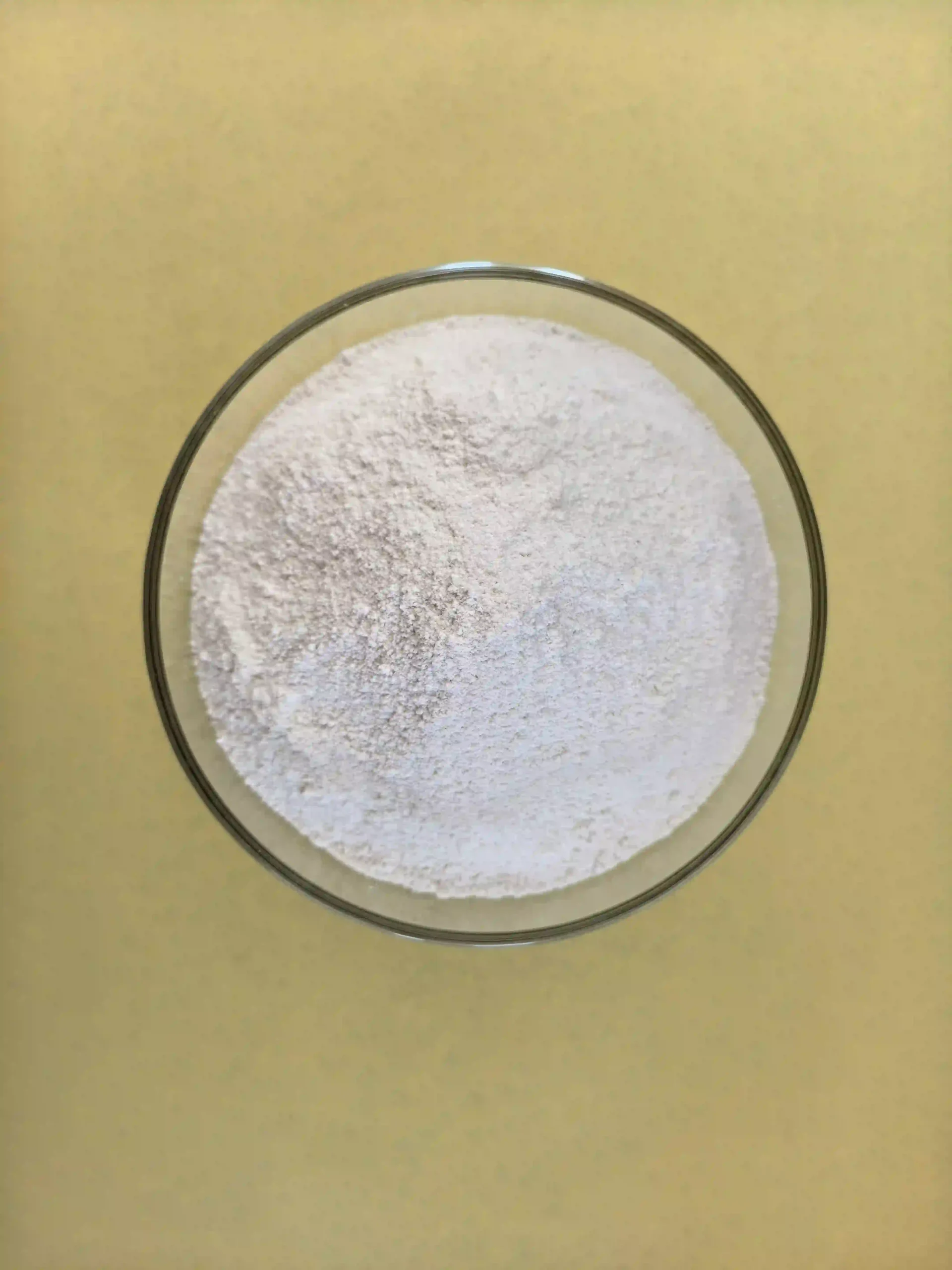

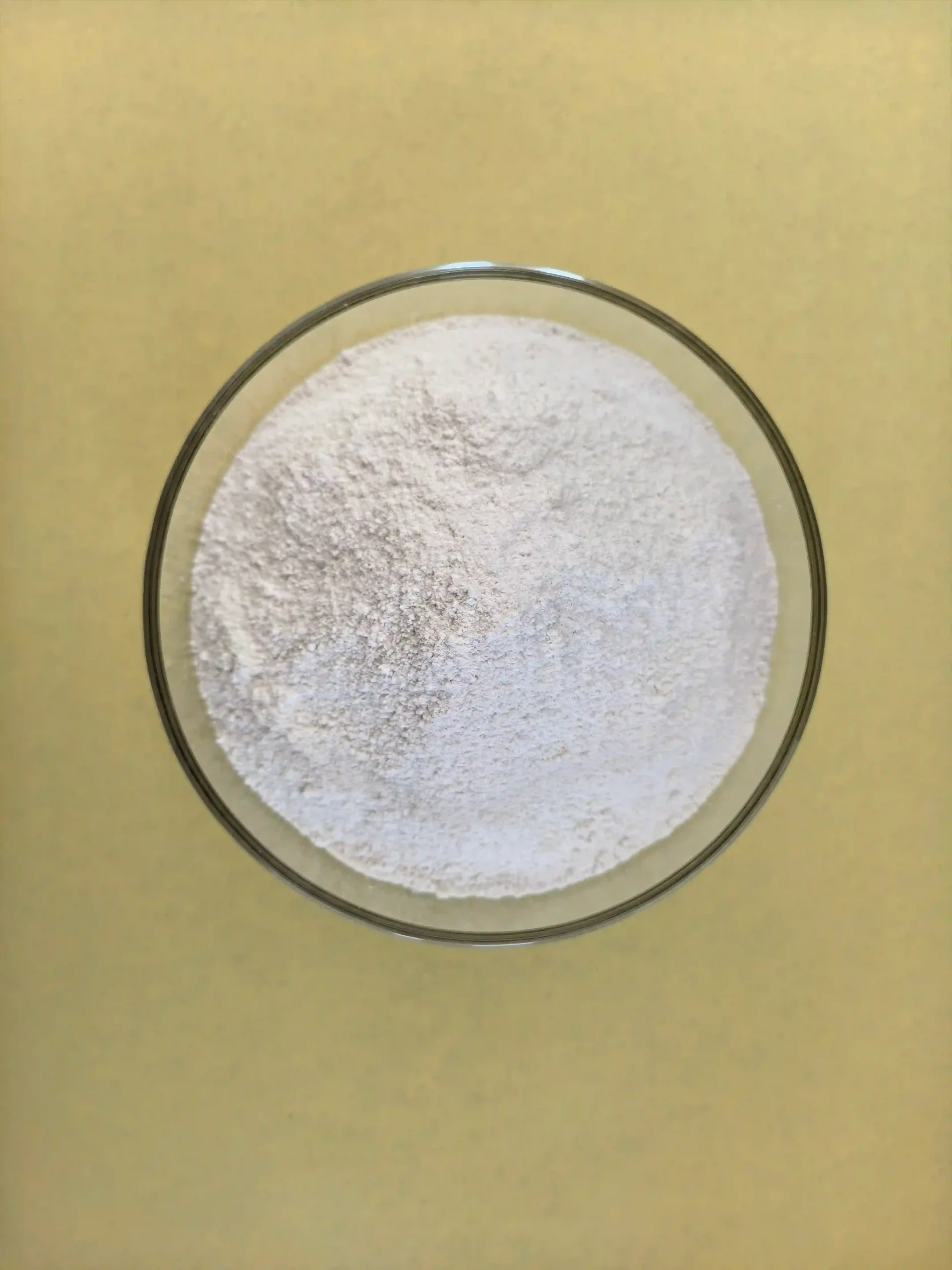

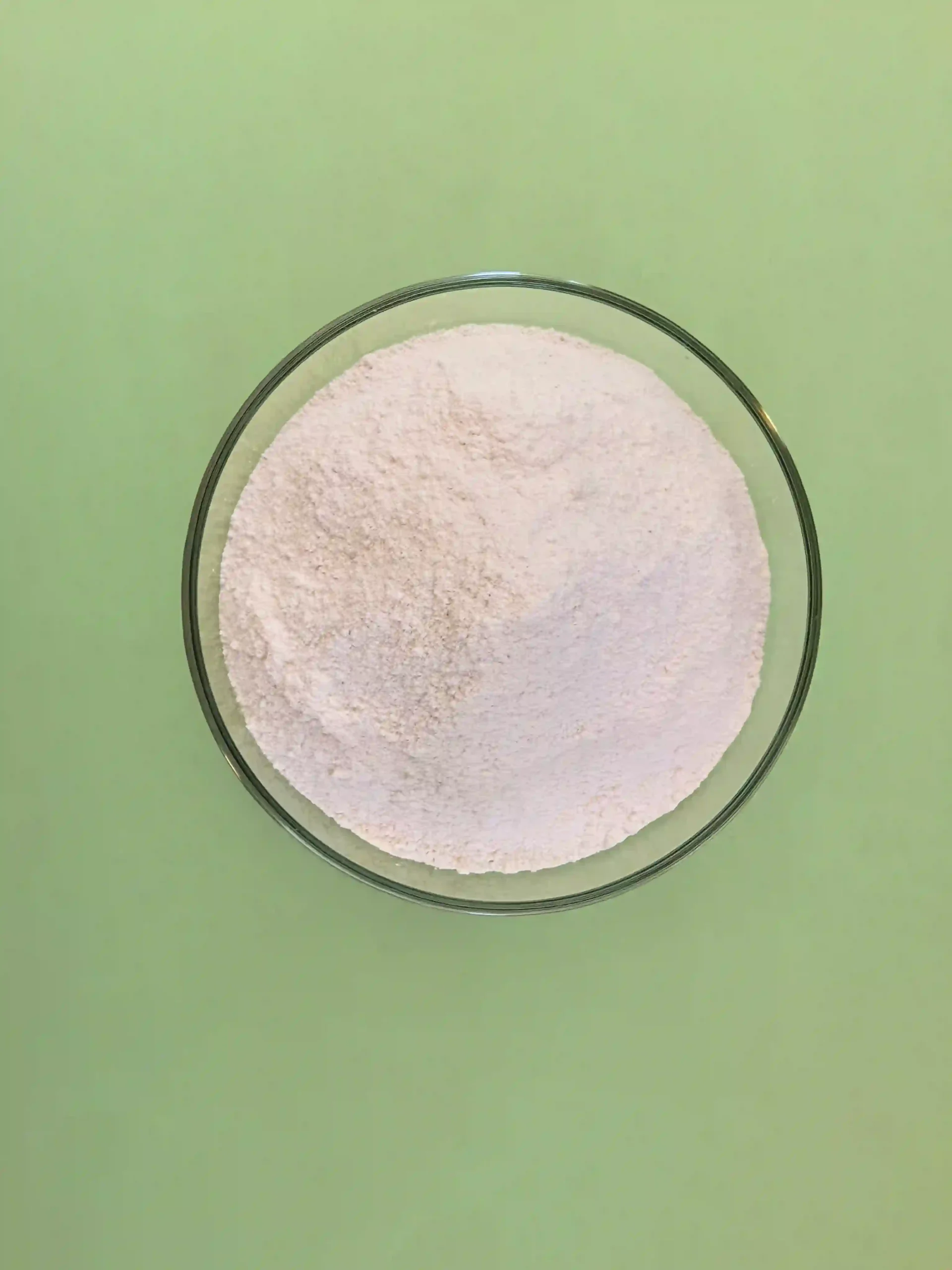

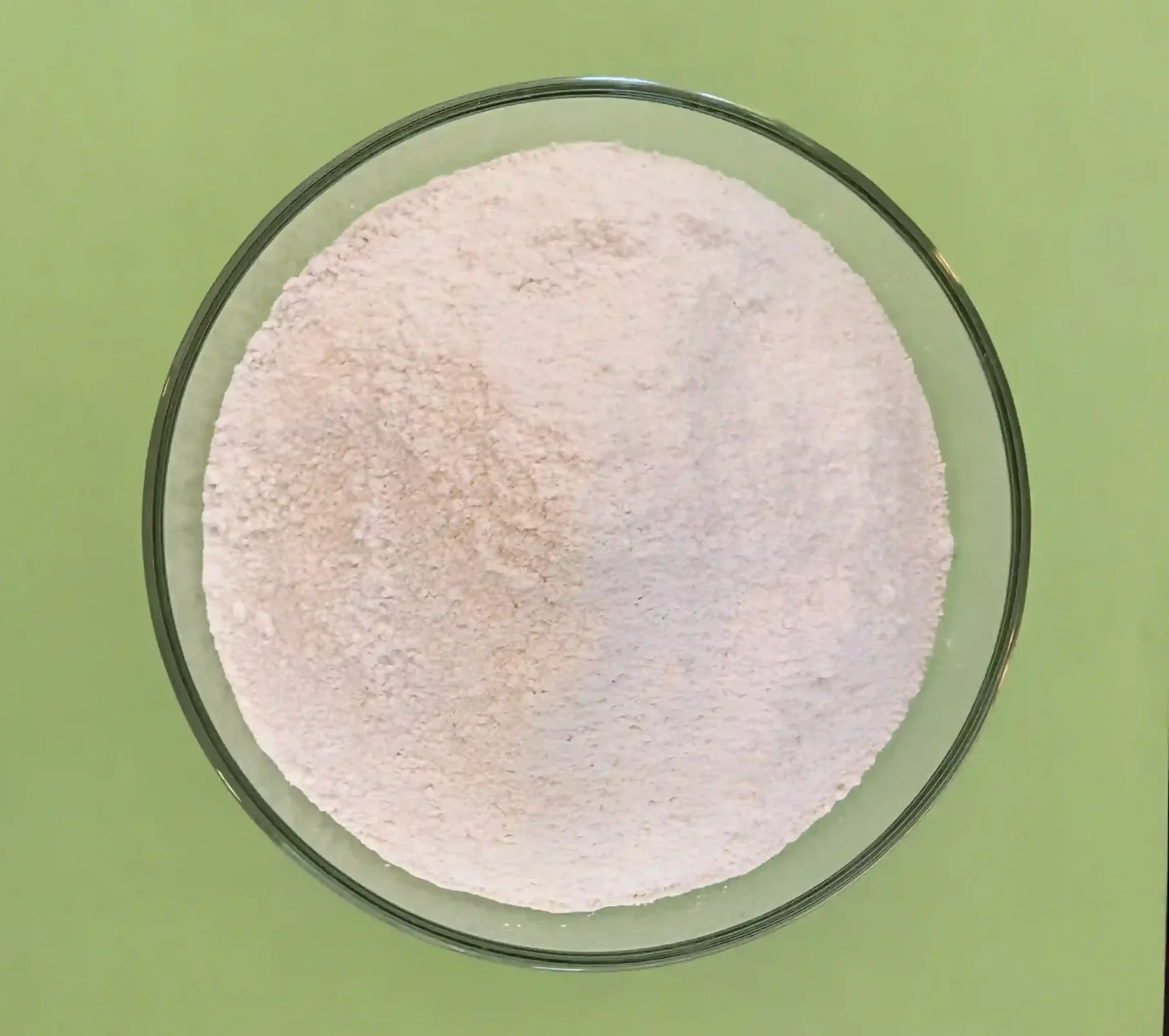

active zinc oxide

Product Categories

Blog

Active Zinc Oxide

Active zinc oxide is a high-functional nano-scale or submicron-scale zinc oxide. Compared with ordinary zinc oxide (indirect method zinc oxide), it features a smaller particle size, a larger specific surface area, higher chemical activity, and unique physical and chemical properties. It is not a new substance but a special form of zinc oxide.

Characteristics of Active Zinc Oxide

Particle size: Nano-scale (usually < 100nm) or submicron-scale Specific surface area: Extremely large (usually > 30 m²/g)

Particle morphology: Spherical, acicular, etc.

Activity: Very high, with large surface energy and low heavy metal content

Application performance: Low dosage, with significant performance enhancement effects

Main Preparation Methods

Wet Methods

- Zinc carbonate decomposition method: React zinc salts with sodium carbonate to generate zinc carbonate, followed by calcination and decomposition.

- Zinc hydroxide decomposition method: React zinc salts with alkalis to produce zinc hydroxide, which is then decomposed through calcination.

Sol-Gel Method

This method can prepare high-purity, ultra-fine nano-zinc oxide, but it has a relatively high cost and is mainly used in high-end fields.

Main Application Fields

Rubber Industry (The Largest Demand Sector)

- High-efficiency vulcanization activator: Active zinc oxide is an indispensable component in rubber vulcanization. Its large specific surface area can more effectively promote the decomposition of vulcanizing agents (such as sulfur), greatly improving vulcanization efficiency and making vulcanization faster and more thorough.

- Reduced dosage: To achieve the same or even better vulcanization effect, its dosage is only 30%-50% of that of ordinary zinc oxide, lowering costs and minimizing zinc residue in products.

- Performance enhancement: It can significantly improve the wear resistance, tear resistance, elasticity, and aging resistance of rubber products. It is widely used in tires, conveyor belts, hoses, seals, and shoe soles, among other applications.

Coatings and Ceramics

- Ultraviolet (UV) screening agent: Nanoactive zinc oxide has strong absorption and scattering capabilities for ultraviolet rays (UVA and UVB), making it suitable for manufacturing UV aging-resistant coatings and sunscreen cosmetics.

- Antibacterial agent: It can generate reactive oxygen species under light or humid conditions, exhibiting long-lasting and broad-spectrum antibacterial and antifungal properties. It is used in antibacterial coatings and ceramic glazes.

- Ceramic flux: Reduces the sintering temperature and improves the compactness and gloss of ceramics.

Electronic and Optoelectronic Fields

- Varistors: It is a key material for manufacturing zinc oxide varistors, which are used for circuit overvoltage protection (such as surge arresters and household appliance protection).

- Transparent conductive films: Aluminum-doped zinc oxide can be used as a substitute for ITO (Indium Tin Oxide) in touch screens, solar cell electrodes, etc.

- Semiconductor material: It is a raw material for preparing zinc oxide-based semiconductor devices, gas sensors, and ultraviolet detectors.

Chemical Catalysis

It serves as a high-efficiency catalyst and catalyst support in chemical processes such as methanol synthesis and desulfurization.

Other Fields

- Animal husbandry: Used as a zinc nutritional supplement with high bioavailability.

- Plastics: Endows plastics with UV resistance and antibacterial properties.

- Pharmaceuticals: Used in ointments for their astringent and anti-inflammatory effects.

Active zinc oxide is an upgraded product of traditional zinc oxide, with its core value lying in “quality replacing quantity” and “function empowerment”. It is not only a key material for the rubber industry to move towards high efficiency and environmental friendliness, but also an important functional raw material in high-tech fields such as new materials, new energy, and biomedicine due to its nano characteristics. With the advancement of nanotechnology and dispersion processes, its application prospects will be even broader.