Find Our Products

Granular Zinc Oxide

Product Categories

Blog

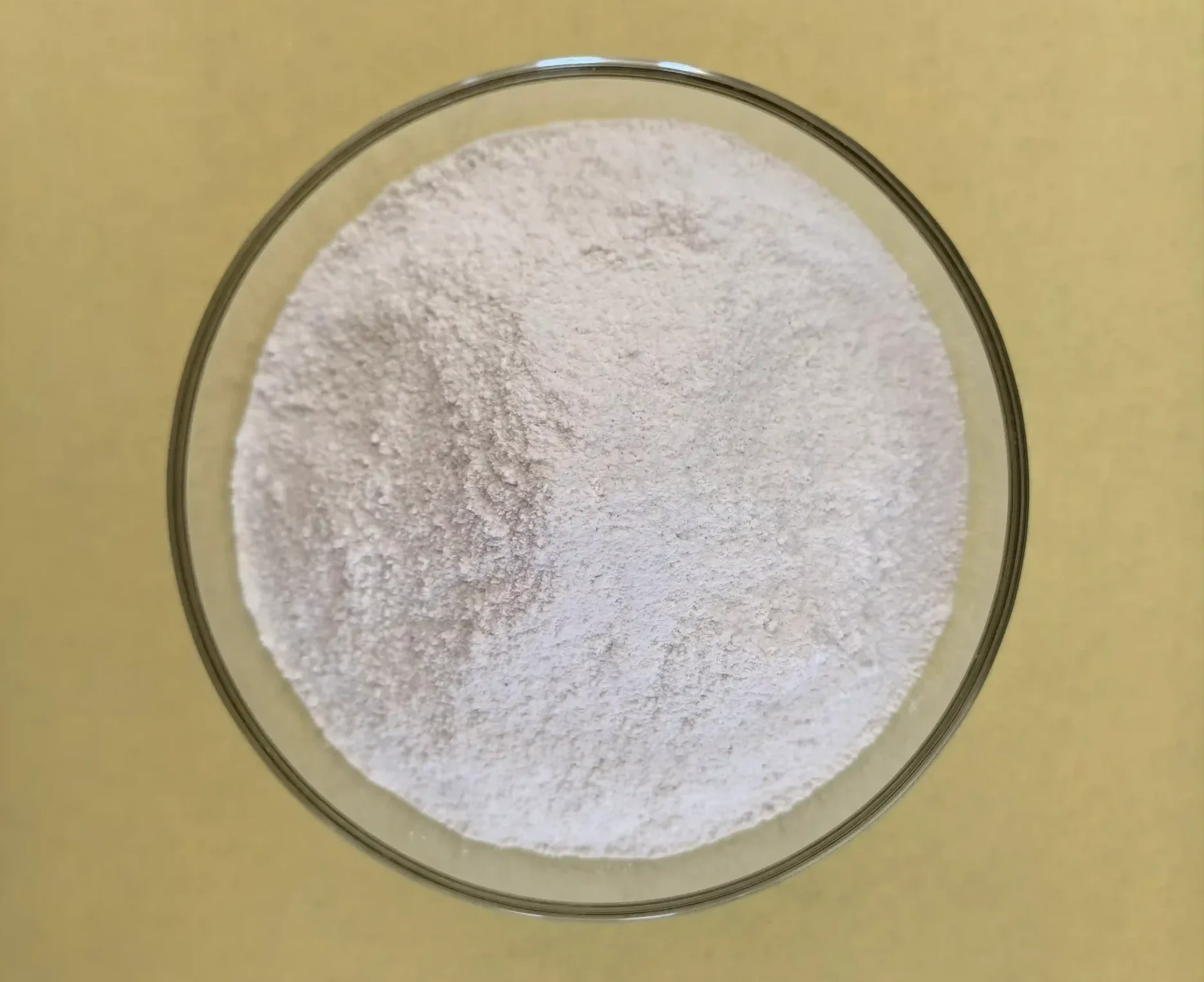

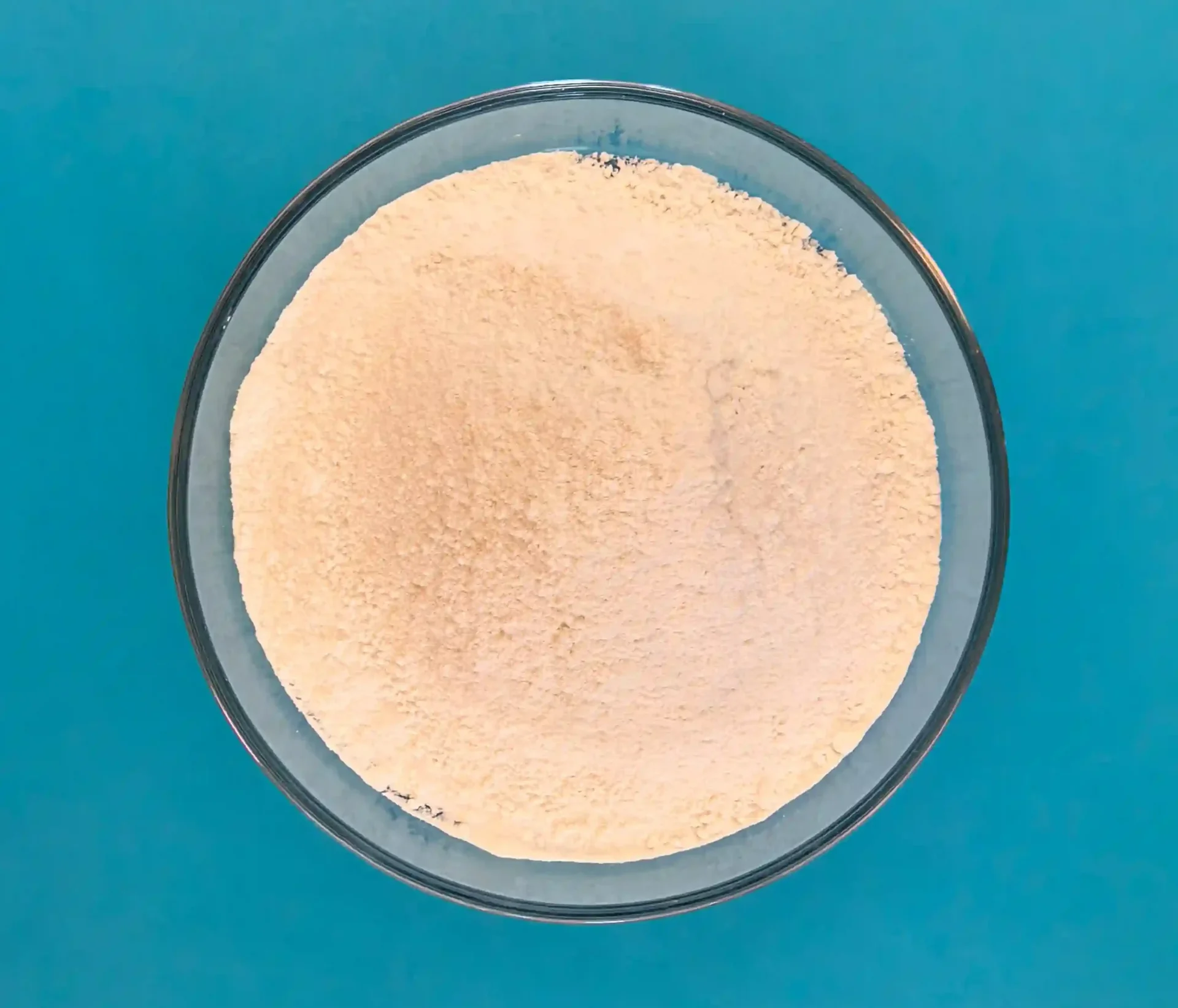

Granular Zinc Oxide

Granular zinc oxide, also known as zinc white powder, has the chemical formula ZnO and is an important inorganic compound. Compared with common powdered zinc oxide, its granular form offers distinct advantages in storage, transportation, and specific application scenarios.

Key Properties

1.Physical Form

It appears as white or slightly yellow fine granules with excellent fluidity. It is not prone to dusting, facilitating automatic metering and feeding.

2.Chemical Properties

As an amphoteric oxide, it can react with acids to form salts and with strong bases to form zincates. It is stable at room temperature, turns yellow when heated, and reverts to white upon cooling.

3.Functional Characteristics

High Specific Surface Area and Activity: The interior of the granules is usually composed of fine crystals, retaining high chemical activity.

Ultraviolet Shielding Capacity: It exhibits excellent absorption and scattering effects on both UVA and UVB, making it an efficient physical sunscreen agent.

Antibacterial and Anti-inflammatory Properties: It can slowly release zinc ions, possessing broad-spectrum antibacterial activity and the function of promoting wound healing.

Catalytic and Optoelectronic Performance: It is an important semiconductor material with catalytic, piezoelectric, optoelectronic, and other properties.

Main Production Processes

Direct Method

- Raw Materials: Zinc ingots, zinc dross, or zinc ore.

- Process: Raw materials are reduced and gasified into zinc vapor at high temperatures (approximately 1000°C). The zinc vapor reacts with oxygen in the air to form zinc oxide, which is then condensed, collected, and granulated.

- Characteristics: Mature technology, large output, relatively low cost. The product has slightly lower purity (usually 95%-99%) and contains small amounts of impurities such as lead and cadmium.

Indirect Method

- Raw Materials: High-purity zinc ingots.

- Process: Zinc ingots are melted and gasified at high temperatures. The zinc vapor is oxidized in an oxidation chamber to generate high-purity zinc oxide, which is then granulated.

- Characteristics: High product purity (up to 99.5%-99.9%), extremely low impurity content, and superior physical and chemical properties, but higher cost.

Wet Chemical Method

- This method includes precipitation, sol-gel, and other techniques, which can prepare nano-zinc oxide, followed by granulation through special processes.

- Characteristics: Precise control over particle morphology and size, high product activity, mainly used in high-end fields.

Features of Granular Zinc Oxide

1. Fine granular structure with excellent fluidity and no dusting.

2. Low dust pollution, providing a better working environment.

3. Good fluidity, enabling convenient automatic conveying and metering.

4. Not prone to caking during storage and transportation.

Granular zinc oxide is an important industrial raw material integrating functionality, practicality, and economy. Its primary application areas include large-scale industrial production such as rubber, ceramics, and feed.